Energy Harvesting Skin Generates Power from Air Conditioners

페이지 정보

작성자 최고관리자 작성일 11-04-20 12:25 조회 391회본문

Energy Harvesting Skin Generates Power from Air Conditioners

Devices that harvest ambient energy from the surrounding environment have become popular since, for some applications, they eliminate the need for batteries that must constantly be replaced. One of the most widely available forms of ambient energy is vibration, which occurs in buildings, machines, bridges, staircases, and the human body, among other places. The most common type of device used to harvest vibration energy is the cantilever, which generates electricity by bending. In a new study, researchers have developed an energy harvesting (EH) device in the form of a flat skin rather than a cantilever, and have shown that it can generate enough power to operate multiple wireless sensor nodes.

The researchers, Soobum Lee from the University of Notre Dame in the US and Byeng Youn from Seoul National University in South Korea, have published their study on the EH skin in a recent issue of Smart Materials and Structures and IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control. The research was partially supported by the POSCO Genesis Program.

“EH skin is a new and innovative design paradigm for vibration and thermal energy harvesting,” Youn told PhysOrg.com. “The EH skin was proposed to overcome the disadvantages of a traditional cantilever-type EH device and enables a power-generating skin structure. The cantilever-type EH devices require a bulky device fixture, resulting in significant energy loss due to imperfect clamping. To the contrary, the EH skin enables a compact and highly efficient EH implementation as a part of a vibrating structure.”

The EH skin works by taking advantage of the piezoelectric effect, which is the ability of some materials to produce electricity when subjected to mechanical stress. Previous research has shown that PZT (lead zirconate titanate) has the highest energy conversion efficiency compared to other piezoelectric materials.

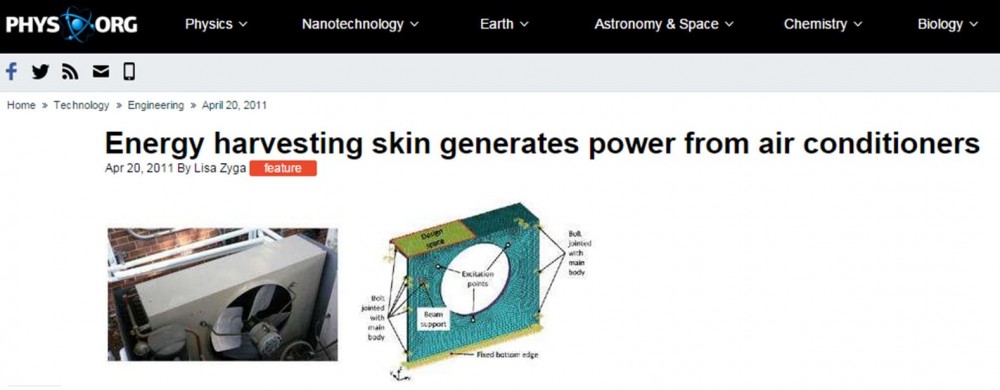

In the new study, the researchers designed and fabricated a skin made of thin PZT patches, which are directly attached to a vibrating surface using a conductive epoxy. As the researchers explained, attaching thin piezoelectric patches is a well-known method for vibration control. However, the patches have never been used to harvest energy, as far as the researchers know.

In their experiments, the researchers used the piezoelectric skin to harvest the vibrations of a condensing unit in an outdoor air conditioner. They optimized the topology and the shape of the piezoelectric skin so that it would convert the condensing unit’s vibrations into electricity as efficiently as possible. The design concept is based on a segment-type design scheme, introduced by the researchers in an earlier study, that segments piezoelectric patches to eliminate the energy cancellation effect.

When testing the skin, the researchers found that it could generate power at an average of 3.7 mW, which is sufficient for operating wireless sensor units. As the researchers explained, self-powered wireless sensors could eliminate the need for battery replacement, leading to significant cost savings.

“According to the US Department of Energy, maintenance costs for battery use in wireless sensor applications are estimated at $80-500 per replacement, including labor, which exceeds the sensor’s cost,” Youn said. “At the same time, about half a billion wireless sensor nodes were consumed by 2010, according to ON World, and this consumption will continue to grow substantially over the years. If EH skin is successfully implemented for self-powered wireless sensors, sustainability and maintainability will be significantly improved with a great economic gain.”

Some of the applications of wireless sensors include the structural health monitoring of buildings as well as building automation systems, which monitor and control the mechanical and lighting systems in a building.

“Building automation is one of the key research areas in the future that can enhance the energy sustainability of buildings by reducing electric energy consumption in lighting by 60%, in climate control by 45%, and in heating by 25%,” Youn said, citing a 2007 LonMark survey carried out by researchers at Technical College Biberach in Germany. “This is possible by monitoring the temperature, humidity, and motion using self-powered wireless sensors. The application of the self-powered sensors to the prognostics and health management area will enable smart health monitoring systems, which are free from battery replacement, to anticipate system failure in advance and make an optimal decision on maintenance. This will reduce maintenance costs significantly in many engineering fields, such as (nuclear) power plants, transportation, buildings, automotives, and defense applications.”

In the future, the researchers plan to utilize multiple vibration modes in the EH skin to significantly enhance the power conversion efficiency. They also plan to develop a multifunctional EH skin that can perform energy harvesting, energy storage, noise reduction, and load carrying. Future applications could also include using the EH skin in aircraft and ground vehicles.

관련링크

- 이전글서울대학교 산업AI 전문인력 양성사업단, 제1회 사업 성과발표회 개최 23.02.14

- 다음글지하철 벽면-에어컨 실외기 등에 타일처럼 붙이면 진동이 에너지로 11.05.20